Newline Solution Pvt. Ltd. is our recent diversification to reduce the Plastic footprint created by us and our customers. At Newline Solutions, we are using latest machinery consisting of high-end cutters, extruder and die cutting granulator technology.

MLP (Multilayered Plastic) waste is collected from nearest available sources and converted into pellets for use in Outdoor Furniture, Plastic Roads, Traffic Cones, Trash Bin, Pipes, etc. We are also assisting our customers in fulfilling their EPR (Extended Producer Responsibilty) under Plastic Waste Management Rules 2018. We collect the waste on behalf of customers and provide EPR Certificate authorised and sealed by Regional Pollution Control Department.

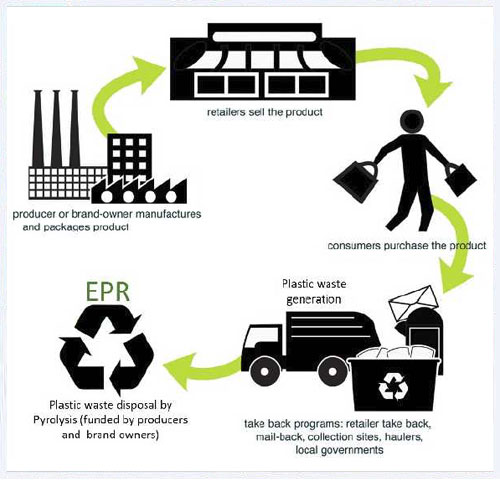

Extended Producer Responsibility (EPR)

Extended Producer Responsibility is a legislative strategy used by most industrialised nations to promote reuse, recycling, and eco-friendly disposal of polymer waste. EPR assigns the responsibility of disposal of this waste to the manufacturer of the goods. For example, disposal of flexible packaging used for food items, consumer goods, and water bottles is assigned to consumer goods manufacturers under EPR.

Extended Producer Responsibility is a legislative strategy used by most industrialised nations to promote reuse, recycling, and eco-friendly disposal of polymer waste. EPR assigns the responsibility of disposal of this waste to the manufacturer of the goods. For example, disposal of flexible packaging used for food items, consumer goods, and water bottles is assigned to consumer goods manufacturers under EPR.

At the centre of EPR lies a closed loop approach to manage products, whereby waste generated from a product is used to produce another product. This approach ensures the price of the product includes the cost of its safe disposal. Therefore, this approach significantly reduces the environmental impact of the waste as well as leads to lower cost of production for the new product.

In practice, if a manufacturer introduces 100MT of polymer packaging material in the market, then it is responsible for collection and disposal of 100MT of post consumer plastic waste. The company may also delegate this responsibility to a Producer Responsibility Organization (PRO). A PRO is paid by the manufacturer for collection and safe disposal of plastic waste. Since EPR has shifted the burden of waste disposal from governments to these product manufacturers, it has driven the adoption of innovative product and packaging strategies leading to reduction in plastic waste Broadly, plastic waste can be classified into recyclable and non-recyclable waste.

Recyclable plastic waste can be physically recycled using technologies such as remoulding. Examples of this type of plastic waste include segregated and more than 95% pure Polyethylene, Polypropylene (PP) plastic waste. End-of-life plastic waste cannot be physically recycled. Examples of this type of plastic waste include Post consumer laminate waste (PCLW). This plastic waste can not be physically recycled by remoulding and incineration of such plastic waste is banned in most developed countries. Hence chemical recycling of this plastic waste by pyrolysis or hydrolysis is the only way for disposal of this end-of-life plastic waste.

EPR is applicable in India from 2018. Each company submitting its EPR plan must now recover 20% of the Multilayered Plastic (MLP) it produces within a year, and 100% within three.